Firms are reactive to better enforcement of emission controls. This effect is more apparent among firms in industries with higher pollution intensity

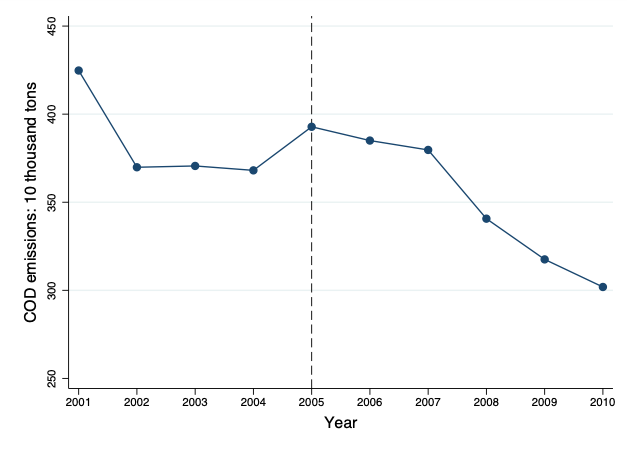

From 2006 to 2010, emissions of major regulated water pollutants, such as chemical oxygen demand (COD), from Chinese manufacturing fell by 23.1% relative to the 2005 level, while manufacturing output was boosted by 137.5%. When looking into the pattern of clean-up (shown in Figure 1), we find this turning point first appeared in 2006. This coincides with the start of China’s 11th Five-Year Plan, characterised by stringent emission target control and enforcement.

Figure 1 Chemical oxygen demand emission in Chinese manufacturing

Have these regulations contributed to the clean-up? If so, how large is the effect? And more importantly, what are the main driving forces underlying the effect? Our latest research may provide insight into these questions, using comprehensive Chinese firm level datasets from multiple sources (Fan et al. 2019).

Emission control in China: Three facts

Even though emissions target control was established in the 1980s in China, these regulations were not treated seriously until the 11th Five-Year Plan, from 2006 to 2010. By means of a set of primary analyses, we document three stylised facts pertaining to COD emissions from manufacturing in China from 2001 to 2010, covering the 11th Five-Year Plan period.

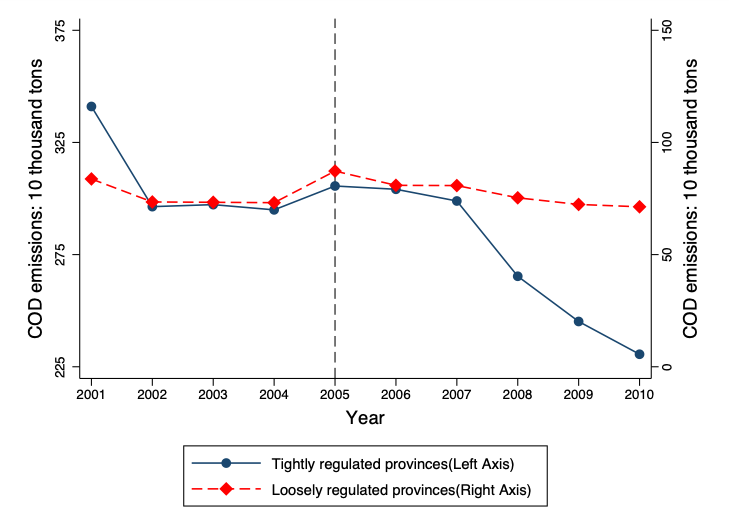

1. Regulation level: As shown in Figure 2, in response to different levels of environmental regulation, firms located in tightly regulated provinces (those assigned with larger COD reduction targets above the median) reduced more pollutants in comparison to their counterparts in loosely regulated provinces (those with COD reduction targets lower than the median).

Figure 2 COD emissions in manufacturing in tightly and loosely regulated provinces

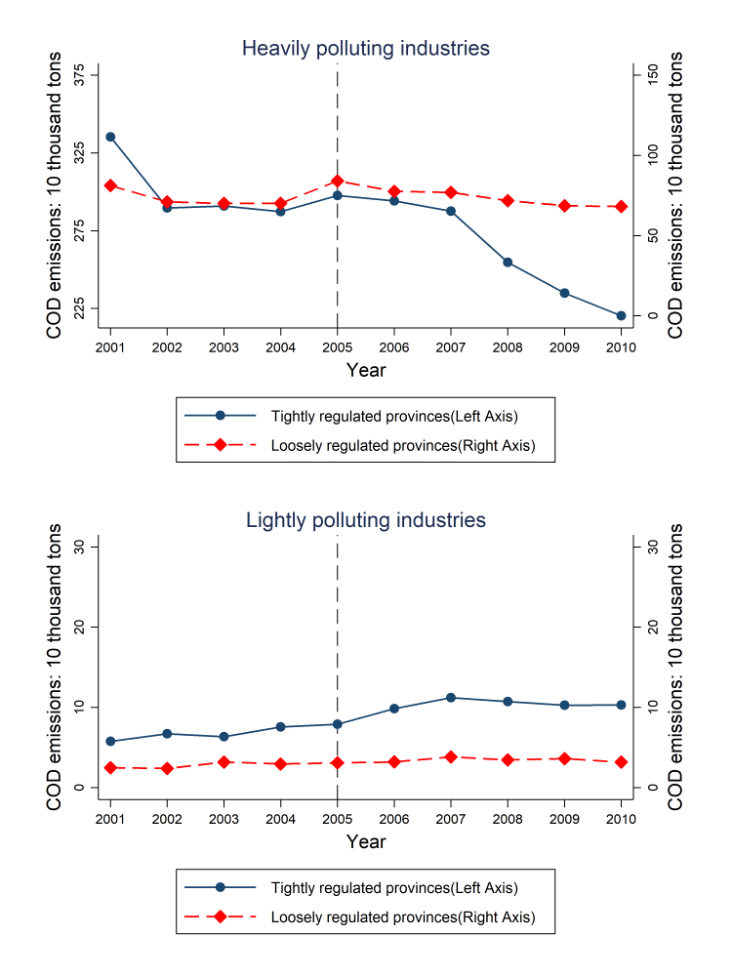

2. Polluting intensity: The effect of environmental regulation stringency on firms’ COD emissions varied across industries with different polluting intensity: Regardless of their location in tightly or loosely regulated provinces, firms in heavily polluting industries all experienced declines in COD emissions. Conversely, COD emissions of firms in lightly polluting industries that were located in tightly regulated provinces increased their emissions during the same time period (Figure 3). This might suggest that industrial pollution intensity positively reinforces the effect of environmental regulation on firms’ pollution reduction.

Figure 3 COD emissions in manufacturing with different pollution intensities in tightly and loosely regulated provinces

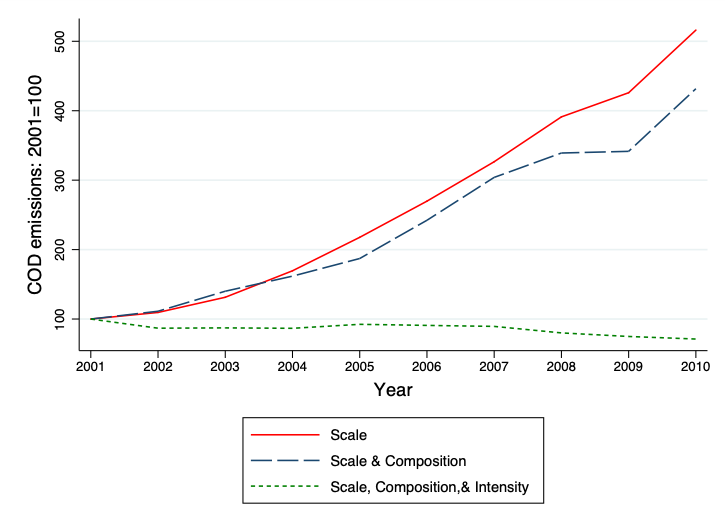

3. Manufacturing emissions: Following Levinson (2009), we decompose changes in total manufacturing COD emissions that can be explained by “composition effect” (adjustment of market share of each industry) and “technique effect” (lowered pollution intensity brought by technological progress). Figure 4 illustrates how both effects exist, whilst the “technique effect” is the predominant causal factor accountable.

Figure 4 Decompostion of the three main effects causing COD emissions in Chinese manufacturing

The findings: Firms’ adjustments to stricter environmental regulation

The above three facts provide intuitive evidence that strengthening emissions reduction control enforcement and greater controls on industrial pollution intensity have positive effects on firms’ pollution control. After rigorous analyses, our main findings are as follows.

Pollution has been reduced due to better enforcement of emission target control and “technique effect” is the predominant cause of emission reduction. We find that more stringent environmental regulations faced by firms are positively associated with a greater probability of reducing COD emissions after 2006.

A within-firm decomposition further shows that around 30% of the emission reduction can be explained by within-firm “scale effect”, which is a drop in firms’ total output. The remaining 70% can be explained by within-firm “technique effect”, including but not limited to the adoption of pollution abatement facilities, the introduction of cleaner production processes, and recycling energy inputs.

There exist industrial heterogeneous effects. Considering the large variation in COD emission across industries, we find that firms that belong to heavily polluting industries located in cities with more stringent environmental regulations cut down much more on pollutants, compared with their intra-city counterparts in less-polluting industries.

Implications: Emissions regulations do have an impact

- Stricter environmental penalties, decreasing industrial wastewater discharge, recycling industrial water, and the adoption of pollution control devices are four main mechanisms linking stricter regulation to reduced emission.

With the stricter target control system in place, firms face a higher probability of receiving administrative penalties and are more likely to discharge less effluent, to consume less industrial water by recycling water, and to adopt devices that control pollution as well as expand their current pollution treatment abilities.

- The emission target control during the 11th Five-Year Plan period failed to stimulate firms to become innovators.

We find no evidence of increase in green patents and water-related green patent applications, leading us to believe that firms are, nevertheless, reluctant to increase environment-related innovation. This could be attributed to the existence of lower-cost countermeasures, such as pollution abatement facilities, which are sufficient to meet the target.

- Expansion of cleaner industries leads to a cleaner industrial structure.

As firms in heavily polluting industries are more responsive to environmental regulations, their sharply declining output and the pollution intensities of their production provide more evidence of the “composition effect”.

- Firms’ economic performances indicated by their profits, capital, labour and market share have deteriorated.

Also, the relocation of firms to cities with stringent environmental regulation plunged sharply compared with those in loosely regulated cities after 2006, which signifies, to a certain extent, an “internal” variant of the pollution havens hypothesis.

Conclusion: Towards green innovation

These patterns show that as environmental regulations become tighter, firms’ emissions fall. To achieve concrete emissions reduction targets, firms are consciously trading off between production arrangements and COD emissions. Overall, manufacturing firms in China are becoming green. Also, the industrial infrastructure in China is becoming cleaner due to the expansion of cleaner industries, while polluting industries are shrinking.

As firms in heavily polluting industries are more responsive to environmental regulations, their sharply declining output and the pollution intensities of their production provide more evidence of the “composition effect”. In addition, although clear reduction targets set during the 11th Five-Year Plan were effective, they still failed to stimulate firms to adopt effective technology to eliminate more pollutants from the production process, perhaps because other lower-cost countermeasures, such as adoption of pollution abatement facilities, was sufficient to meet the target.

Regulators still face the fundamental challenges of identifying an appropriate regulatory path that will stimulate firms to shift from the adoption of end-of-pipe treatment technology to innovations.

References

Becker, R and V Henderson (2000), “Effects of Air Quality Regulations on Polluting Industries”, Journal of Political Economy 108(2): 379–421.

Berman, E and L T M Bui (2001), “Environmental Regulation and Productivity: Evidence from Oil Refineries”, Review of Economics and Statistics 83(3): 498–510.

Cai, X, Y Lu, M Wu, and L Yu (2016), “Does Environmental Regulation Drive Away Inbound Foreign Direct Investment? Evidence from a Quasi-natural Experiment in China”, Journal of Development Economics 123: 73–85.

Chay, K Y and M Greenstone (2005), “Does Air Quality Matter? Evidence from the Housing Market”, Journal of Political Economy 113(2): 376–424.

Chen, Z, M E Kahn, Y Liu, Yu and Z Wang (2018), “The Consequences of Spatially Differentiated Water Pollution Regulation in China”, Journal of Environmental Economics and Management 88: 468–485.

Greenstone, M (2002), “The Impacts of Environmental Regulations on Industrial Activity: Evidence from the 1970 and 1977 Clean Air Act Amendments and the Census of Manufactures”, Journal of Political Economy 110 (6): 1175–1219.

Fan, H, J S Graff Zivin, Z Kou, X Liu and H Wang (2019). “Going Green in China: Firms' Responses to Stricter Environmental Regulations”, NBER Working Paper No. 26540.

Greenstone, M and R Hanna (2014). “Environmental Regulations, Air and Water Pollution, and Infant Mortality in India”, American Economic Review 104(10): 3038–3072.

Greenstone, M, J A List and C Syverson (2012). “The Effects of Environmental Regulation on the Competitiveness of US Manufacturing”, NBER,Working Paper No. 18392.

Gutiérrez, E and K Teshima (2018), “Abatement Expenditures, Technology Choice, and Environmental Performance: Evidence from Firm Responses to Import Competition in Mexico”, Journal of Development Economics 133: 264–274.

Henderson, J V (1996), “Effects of Air Quality Regulation”, The American Economic Review 86(4): 789–789.

Keller, W and A Levinson (2002). “Pollution Abatement Costs and Foreign Direct Investment Inflows to US States”, Review of Economics and Statistics 84(4): 691–703.

Levinson, A (2009), “Technology, International Trade, and Pollution from US Manufacturing”, American Economic Review 99(5): 2177–2192.

Nelson, R A, T Tietenberg and M R Donihue (1993). “Differential Environmental Regulation: Effects on Electric Utility Capital Turnover and Emissions”, The Review of Economics and Statistics 75(2): 368–373.

Shi, X and Z Xu (2018), “Environmental Regulation and Firm Exports: Evidence from the Eleventh Five-Year Plan in China”, Journal of Environmental Economics and Management 89: 187–200.

Walker, W R (2013), “The Transitional Costs of Sectoral Reallocation: Evidence from the Clean Air Act and the Workforce”, The Quarterly Journal of Economics 128(4): 1787–1835.