Increased demand was seen to induce technology diffusion among garment workers, but willingness of both learner and the teacher is necessary

One important source of the well-documented gap in firm productivity between low- and high-income countries is the use of inferior technology (Syverson 2011, Bloom et al. 2013). Small firms, where the vast majority of the non-agricultural workforce in low-income countries are employed, are particularly far from the technology frontier.

This fact has inspired a variety of firm-level training programmes aimed at increasing productivity of microenterprises. However, meta-analytic evidence suggests these costly interventions generate only modest benefits, necessitating attention to scale and a search for impact multipliers (McKenzie and Woodruff 2014, McKenzie 2020).

Peer-to-peer technology diffusion is a natural candidate for such multiplier effects. Other studies have documented that small-scale farmers adopt new technologies by learning from their peers and that managerial practices spillover between connected non-agricultural firms (Fafchamps and Quinn 2013, 2016, Cai and Szeidl 2017, Foster and Rosenzweig 1995, Conley and Udry 2010, Munshi 2004, Bandiera and Rasul 2006). However, we know little about whether these results generalise to non-agricultural firms. Plus, efforts to introduce new technologies have found little to no organic diffusion through networks of connected entrepreneurs (Atkin et al. 2017b.

In our study (Hardy and McCasland 2021), we find that demand shocks can spur peer-to-peer technology diffusion among microenterprises. This insight is consistent with the broader economics literature on technology adoption (Verhoogen 2020). Several studies use variation in export or domestic market access to demonstrate a causal relationship between demand-side factors and firm-level technology upgrading (Bustos 2011, Atkin et al. 2017a), though none to date have tested whether demand can jump-start broader diffusion of new technologies through a network beyond the individual firm.

Introducing a novel technology

We began by commissioning a custom-designed weaving technology that could serve as a case study in operational technology adoption. The technique has two key features:

- Novelty: the experiment can control introduction of the technique.

- An algorithmic structure: the technique must be simple for a trained garment-maker to quickly learn, if we hope to differentiate between plausible explanations for network-based technology adoption.

Though we do not claim the technique is necessarily profit or productivity enhancing in the short term, it is widely applicable (gender-neutral, can be added to any garment much like embroidery), relevant (customers in our market research survey cite style innovation as a key driver of organic demand), and well-suited to the moment we study (a period of frequent blackouts; unlike embroidery, this technique does not require electricity). The designer dubbed the weave Sharawakil, a portmanteau of the Hausa word Shara, which means twisted, and his surname.

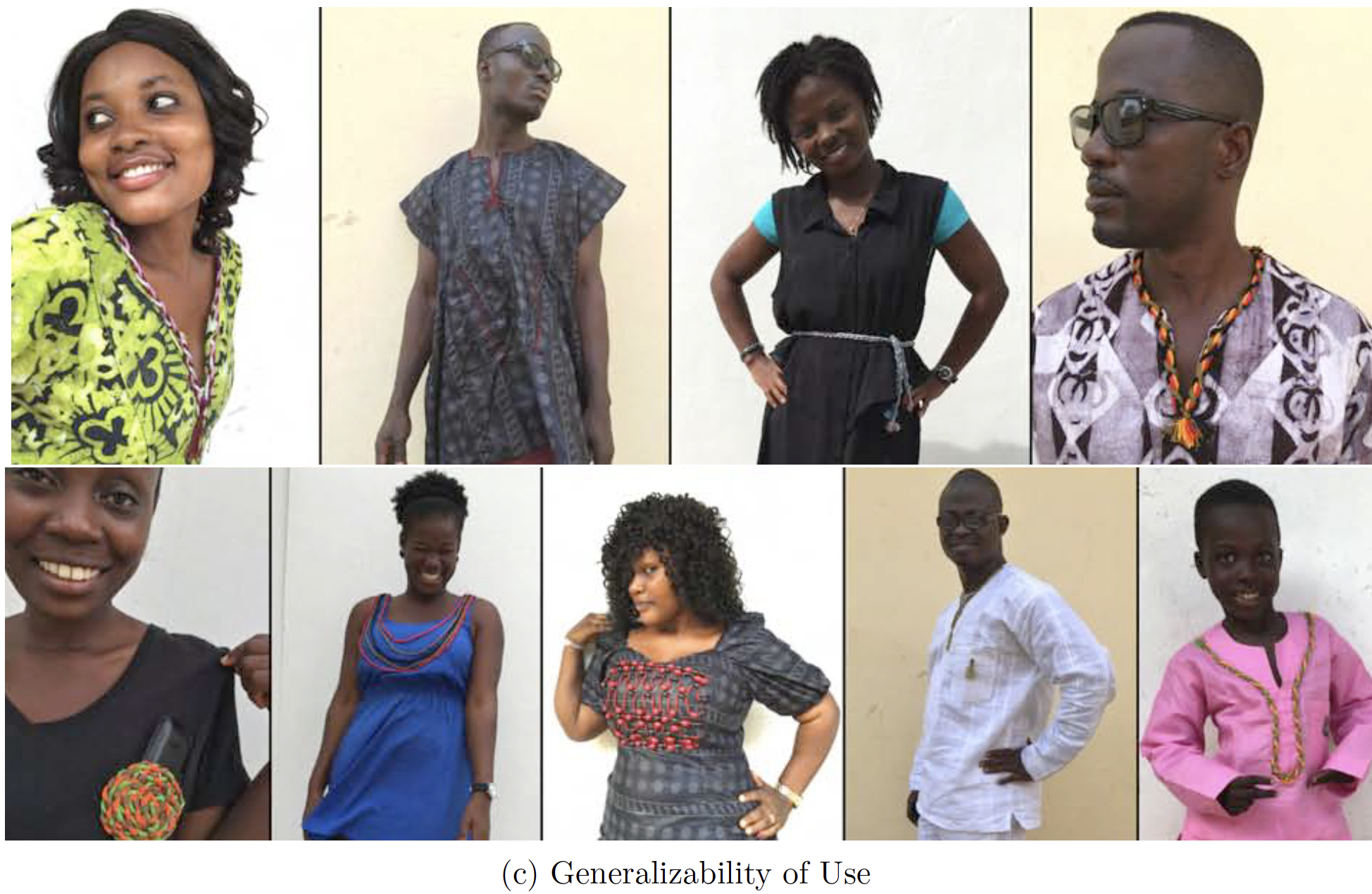

Figure 1 New technology: Sharawakil

Notes: With permission from the models, this figure presents the method, product, and uses of the novel weaving technology used in this study. Photoshoots were conducted at the IPA Ghana Office and in Makola Market, Accra. Models are IPA Ghana staff members and friends and family of the Sharawakil designer, Mr. Osman Mutawakil (pictured top right).

Experimental design

The experiment randomly offered training in the weaving technique to 15% of firm owners in the sample, which includes all firms producing bespoke garments in Hohoe, Ghana, a mid-size district capital in the Volta Region. We partnered with the technical training division of the local government to implement the training. The technique requires the motor mechanism from a commonly available, cheap children's toy. Trainees constructed their own tools and kept them following the training.

In the six weeks following training, about 13% of firm owners invited to the training adopted the design in a customer order, but there was effectively no diffusion to untrained firms.

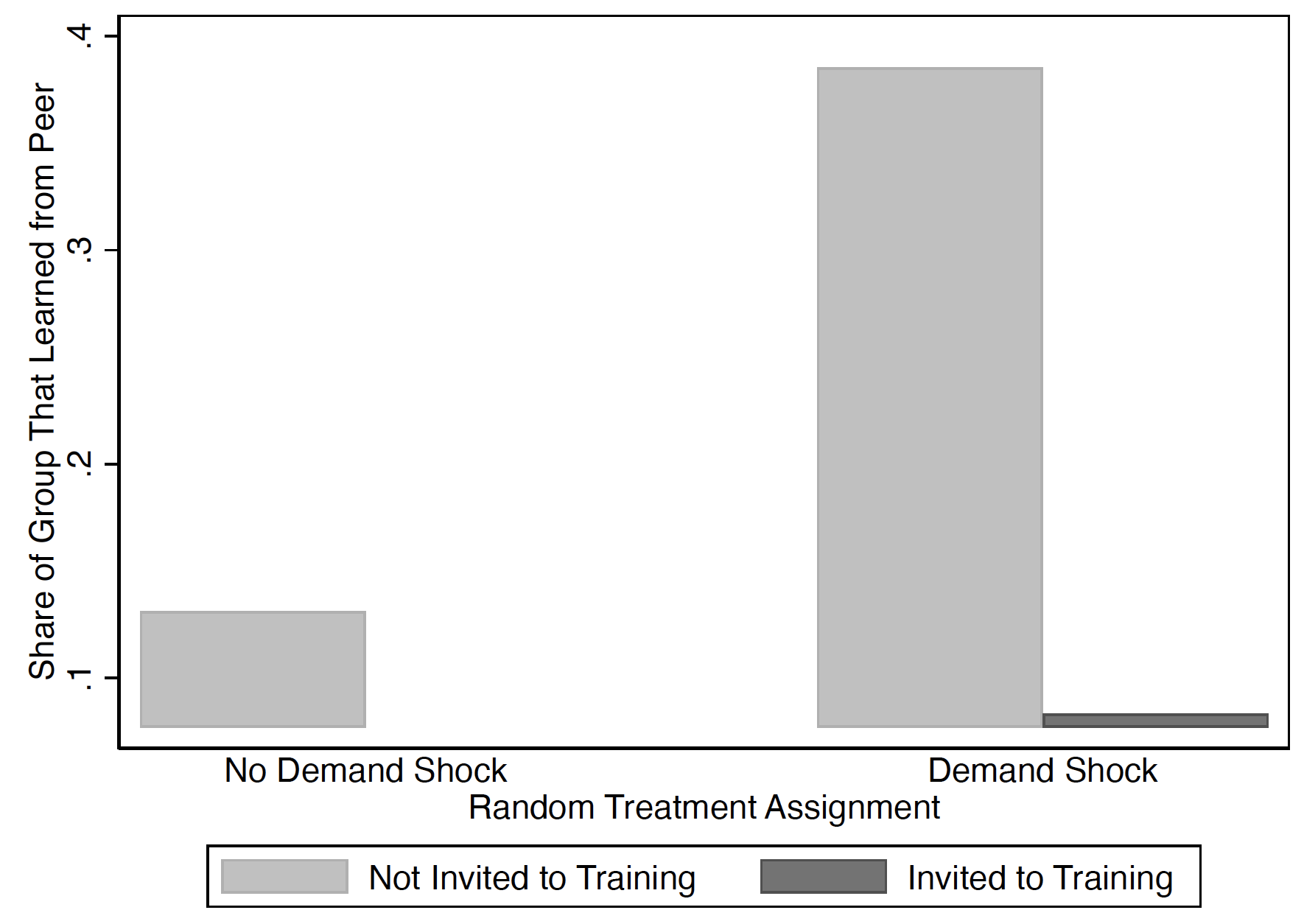

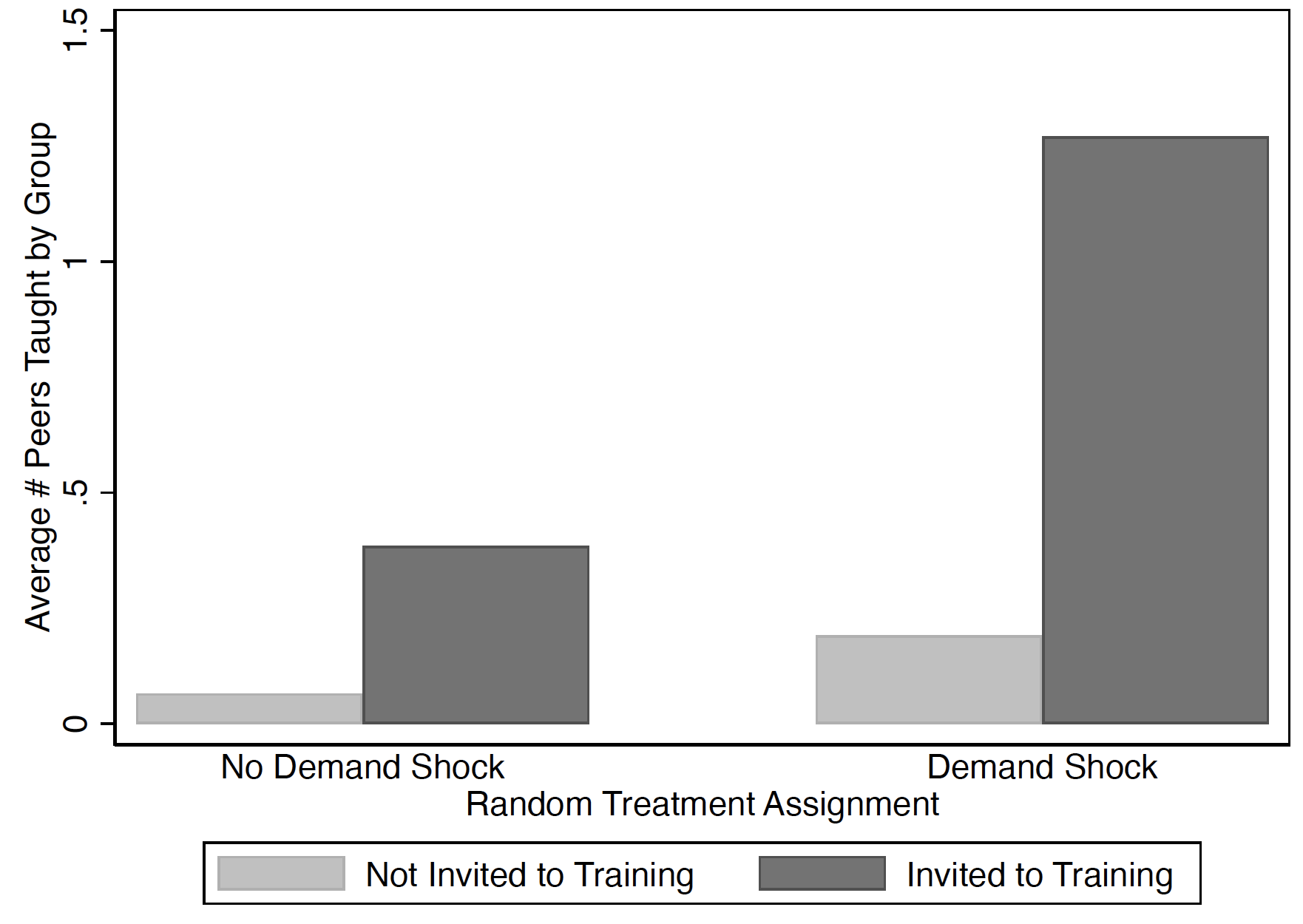

The second phase of the experiment took place about three months after the training. Our implementation team attempted to place orders for garments featuring the design with random subsets of both trained and untrained firms.1 As seen in Figure 2, among trained firm owners, those who received demand shocks taught 400% as many of their peers as those who did not, driving significant peer-to-peer diffusion. This finding holds for learners who received and who did not receive demand shocks. It holds whether we measure an instance of teaching via teacher reports, learner reports, or either. It holds after removing outliers, the most prolific teachers, and estimating using a count model rather than a linear model.

Figure 2 Technology diffusion levels by treatment group

(a) Learning from peers

(b) Teaching to peers

Notes: This figure depicts average learning and teaching behaviour by randomised treatment groups. The universal nature of the sample makes it possible to have complete network data across all local garment makers. Learning and teaching reflect either learner or teacher reported activity during the order period.

Plausible explanations for network-based technology adoption

A simple explanation for the success of the demand intervention might be that firms who use the weave technique to fulfil experimental orders are better at the technique and thus better able to teach it. While the algorithmic design was intended to obstruct this mechanism, we also search for evidence of it in our experiment and fail to find it. Utilising that demand orders were randomly sized, we find no evidence that potential teachers with larger orders teach more, produce weaves of better quality, self-report more confidence in producing the weave, or are more likely to continue using the weave in customer orders a year after the experiment.

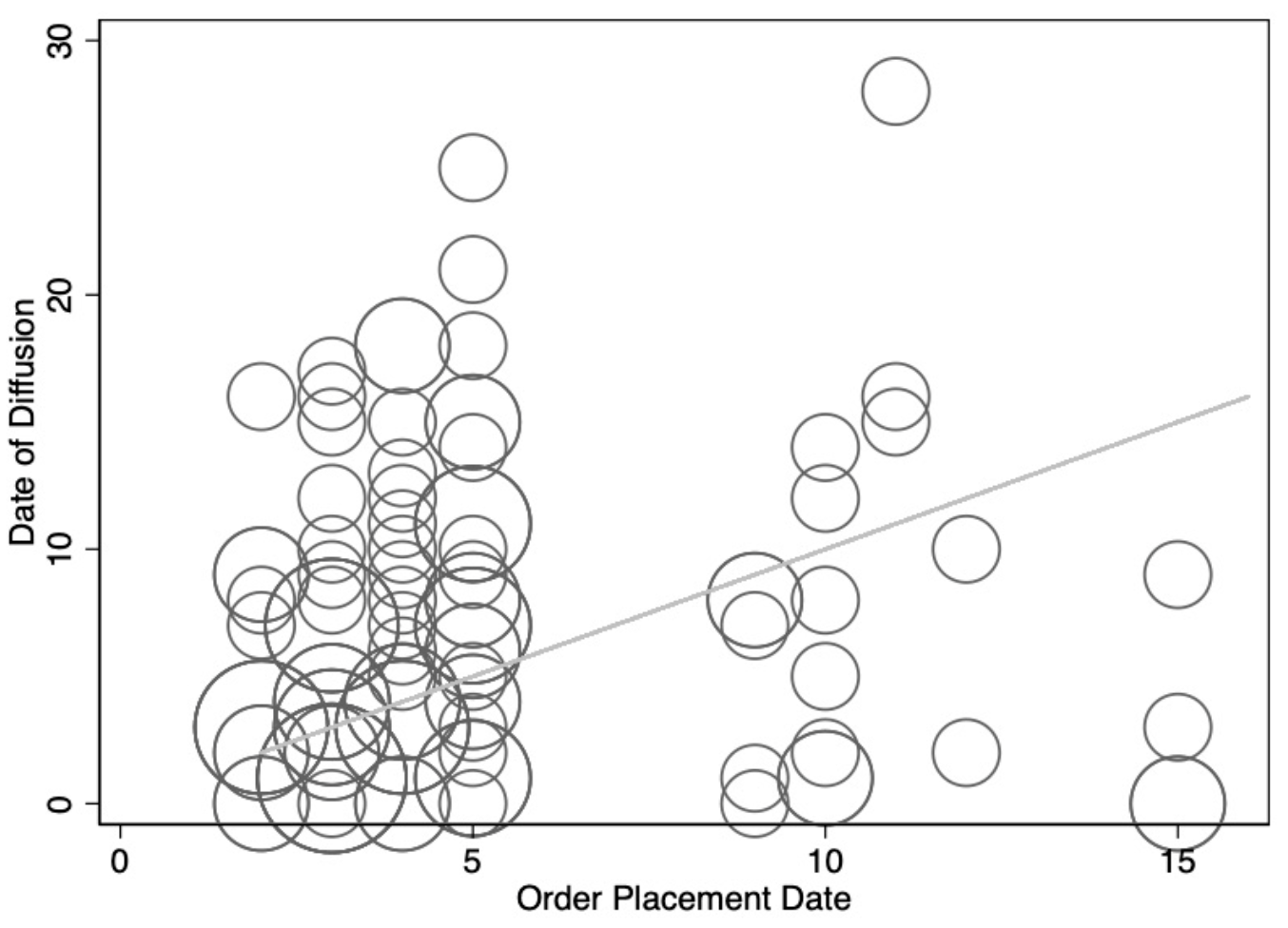

Other potential explanations include differential access to capital and visibility to potential learners. We find no evidence among trained firm owners that those with demand were more likely to have access to the necessary capital to produce the weave. Though we do not have direct data on requests for information or skill-transfer, we utilise the lag between the date orders were placed and the date firms actually worked on them to show that the timing of teaching is dependent on the order date but not on the timing of demand order fulfillment. In other words, trained firm owners taught other garment makers once they received an order from our implementation team regardless of whether or not they had yet used the weaving technology to actually produce that order.

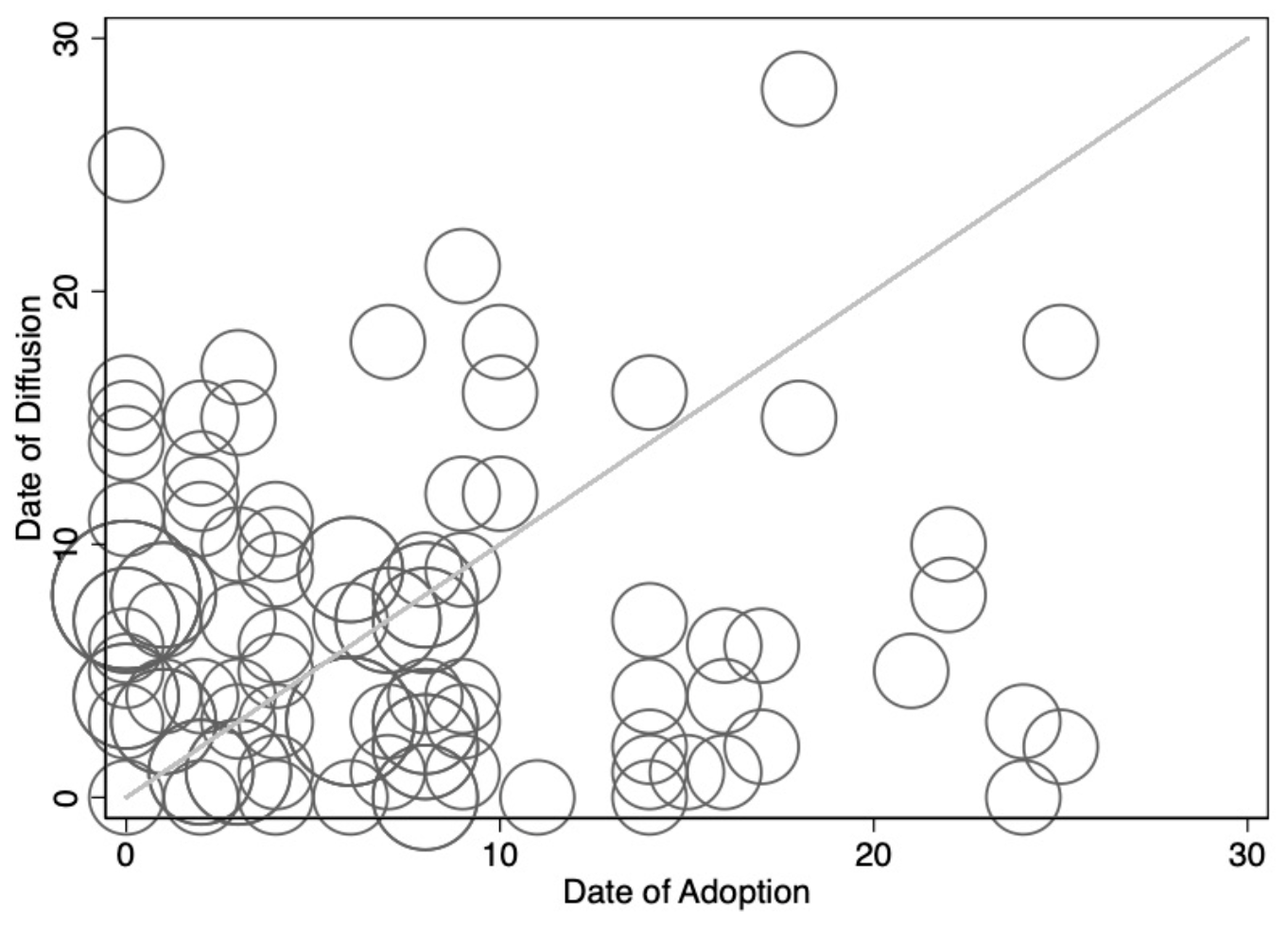

Figure 3 Observing demand, adoption, and diffusion timing

(a) Order placement and diffusion date

(b) Adoption and diffusion date

Notes: Panel (a) depicts a weighted scatterplot of learner-reported date of learning and administratively-recorded date of teacher order placement for learner-teacher dyads. Panel (b) depicts a weighted scatterplot of that same learner-reported date of learning by teacher-reported date of teacher's first use of Sharawakil. The line in each sub-figure represents the 45 degree line, i.e. the same date. Bubbles above the lines signify that the event on the y-axis occurred after the event on the x-axis. Bubbles below the lines signify that the event on the y-axis occurred before the event on the x-axis. Bubbles directly on the line signify that both events happened on the same date. The pattern that emerges in panel (a) is that diffusion took place after orders for teacher-learner dyads in which diffusion occurred. No such pattern is visible in panel (b), suggesting that diffusion and the manufacturing of the weave in teacher firms are not correlated with each other, or that there is no evidence of learning-by-doing.

Results and implications

Absent adoption-based explanations, we interpret our findings to suggest that the demand intervention generated differential willingness among potential teachers by reducing the rivalry of the weaving technique.

Using heterogeneity by teacher and learner characteristics, we find almost no diffusion from any of our experimental groups to their normal competitors (identified by linking customers who shop at the same tailors). All of our effects are driven by trained firms teaching non-competitors. In addition, the wedge between trained firm owners with and without demand is mitigated by owners who self-report more willingness to share rival resources with their peers at baseline. This evidence is consistent with a rivalry interpretation, though we are unable to directly test for it.

Conclusion

Our study suggests that in the presence of a productivity-enhancing training opportunity, it may be possible to magnify impacts by pairing demand shocks with training. This may spur diffusion of new technologies through business networks. The fact that the demand shocks studied in this project were interventionist is perhaps a feature more than a bug as they should be replicable and not rely on organic demand generation.

The findings also suggest that the incentives of both potential learners and teachers are important to consider in understanding the determinants of technology diffusion. In particular, contexts in which demand for new technologies is rival may exhibit diffusion dynamics that are quite different from those where demand is non-rival.

References

Atkin D, A Khandelwal, A Osman (2017a) “Exporting and firm performance: evidence from a randomized experiment”, Quarterly Journal of Economics 132 (2), 551–615.

Atkin, D, A Chaudhry, S Chaudry, A Khandelwal, E Verhoogen (2017b), “Organizational barriers to technology adoption: evidence from soccer-ball producers in Pakistan”, Quarterly Journal of Economics 132 (3), 1101–1164.

Bandiera, O and I Rasul (2006), “Social networks and technology adoption in northern Mozambique”, Economic Journal 116 (514), 869–902.

Bloom, N and J Van Reenan (2007), “Measuring and explaining differences in management practices across countries”, Quarterly Journal Of Economics 122 (4), 1351–1408.

Bloom, N and J Van Reenan (2010), “Why do management practices differ across firms and countries?”, Journal of Economic Perspectives 24 (1), 203–224.

Bloom, Nicholas, Benn, Eifert, Mahajan, Aprajit, McKenzie, David, Roberts, John, 2013. “Does management matter? Evidence from India”, Quarterly Journal of Economics 128 (1), 1–51.

Bustos, P (2011), “Trade liberalization, exports, and technology upgrading: evidence on the impact of MERCOSUR on Argentinian firms”, American Economic Review 101 (1), 304–340.

Cai, J and A Szeidl (2017), “Interfirm relationships and business performance”, Quarterly Journal of Economics 133 (3), 1229–1282.

Conley, T and C Udry 2010, “Learning about a new technology: pineapple in Ghana”, American Economic Review 100 (1), 35–69.

Fafchamps, M and S Quinn (2013), “Social Networks and Business Practices: Evidence from a Randomized Experiment with Microentrepreneurs”, Working Paper.

Fafchamps, M and S Quinn (2016), “Networks and manufacturing firms in Africa: results from a randomized field experiment”, World Bank Economic Review 32 (3), 656–675.

Foster, A and M Rosenzweig (1995), “Learning by doing and learning from others: human capital and technical change in agriculture”, Journal of Political Economy 103, 1176–1209.

Hardy M and J McCasland (2021), “It takes two: Experimental evidence on the determinants of technology diffusion", Journal of Development Economics 149: 102600

Hsieh, Chang-Tai and P Klenow (2009), “Misallocation and manufacturing TFP in China and India”, Quarterly Journal of Economics 124 (4), 1403–1448.

McKenzie, D (2020), “Small Business Training to Improve Management Practices in Developing Countries: Re-assessing the Evidence for “Training Doesn’t Work”, Working Paper.

McKenzie, D and C Woodruff (2014), “What are we learning from business training and entrepreneurship evaluations around the developing world?”, World Bank Research Observer 29 (1), 48–82.

Munshi, K (2004), “Social learning in a heterogeneous population: technology adoption in the Indian green revolution”, Journal Of Development Economics 73, 185–213.

Syverson, C (2011), “What determines productivity?” Journal of Economic Literature 49 (2), 326–365.

Verhoogen, E (2020), “Firm-Level Upgrading in Developing Countries”, Working Paper.

Endnotes

1 The training, implementation, and research teams intentionally had no overlapping staff, to allow for some potential plausible deniability in the link between these activities. We did not, however, attempt to explicitly employ a secret shopper methodology because we doubted whether it would be possible to effectively conceal the source of a wave of orders that touched more than half of the garment making firms in this small town and its outlying suburbs. Like government training, however, the premise of a wave of orders from a non-governmental organization is not unprecedented, or even particularly obscure in this setting.